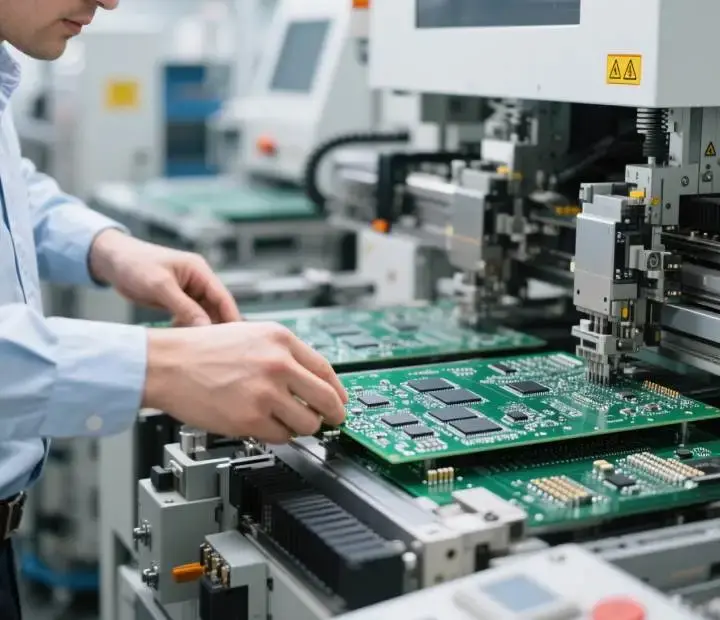

Shenzhen, Guangdong Dec 8, 2025 (Issuewire.com) - FR4PCB.TECH, a globally recognized provider of advanced PCB (Printed Circuit Board) manufacturing and assembly services, has launched its new China 110pcs prototype PCB assembly solution, designed to meet the urgent needs of startups, R&D teams, and innovators seeking rapid prototyping capabilities. This new service offers complete end-to-end support for prototype development, including PCB fabrication, SMT (Surface-Mount Technology) and through-hole assembly, component sourcing, testing, and final logistics. By providing fast turnaround times and high-quality assembly for low-volume orders, FR4PCB.TECH empowers engineers and product developers to validate designs, accelerate innovation, and reduce time-to-market.

The 110pcs prototype solution is ideal for companies developing IoT devices, wearable electronics, industrial control systems, or specialized consumer products, allowing them to produce functional prototypes quickly without committing to large-volume production. This service ensures high reliability, precise assembly, and seamless integration into the final product, bridging the gap between concept and production with minimal delays.

Industry Outlook: Trends Driving Rapid Prototype PCB Assembly

The global electronics industry is experiencing unprecedented growth, driven by digital transformation, the proliferation of connected devices, and rising demand for smart, compact, and reliable electronics. Industries including IoT, consumer electronics, industrial automation, medical devices, and telecommunications increasingly rely on rapid prototyping to accelerate product development cycles and stay competitive in fast-moving markets.

Prototype PCBA services have become critical for companies seeking to iterate designs, test functionality, and validate manufacturability before entering full-scale production. Traditional manufacturing methods, which often require long lead times and high minimum order quantities, are no longer sufficient for modern product development needs. Manufacturers now demand flexible, agile solutions that allow low-volume production runs with consistent quality and minimal risk.

China continues to lead the global PCB manufacturing sector, offering advanced production infrastructure, highly skilled engineers, and efficient supply chain networks. Within this ecosystem, FR4PCB.TECH has established itself as a leading provider of flexible, reliable, and rapid 110pcs prototype PCB assembly solutions, enabling both startups and established enterprises to rapidly move from concept to functional prototype.

Market analysis shows that the global demand for prototype PCB assembly is projected to grow at a strong pace over the next decade, particularly in sectors such as IoT, AI-powered devices, wearable technology, and industrial automation, where rapid iteration and validation are critical for success.

FR4PCB.TECH: Expertise, Capabilities, and Innovation

More On Ournewsnation ::

- Audfly’s Plug-and-Play Directional Audio Modules Drive Faster Deployment Across Kiosks and Smart Terminals

- FurGPT Deploys Smart Bonding Systems for Enhanced Cross-Platform Play

- Colleen Conn, Recognized by BestAgents.us as a 2025 Top Agent

- High-Net-Worth Americans Turn to Caribbean Catamarans for Massive Tax Breaks in 2025

- Shincheonji Tanzania Church Holds Revelation Bible Exam with Local Pastors and Believers

Founded with the mission to deliver high-quality and reliable PCB and PCBA solutions, FR4PCB.TECH has earned a reputation as a trusted OEM and ODM partner for clients worldwide. With comprehensive end-to-end capabilities, the company supports clients at every stage of the product development cycle from initial design to final logistics.

Key service capabilities include:

PCB Fabrication: Multi-layer, high-density, and flexible boards for complex applications.

SMT & Through-Hole Assembly: High-precision assembly lines optimized for both prototype and small-to-medium volume production.

Component Sourcing: Access to a global network of verified suppliers for authentic and traceable components.

Testing & Quality Assurance: Automated Optical Inspection (AOI), X-ray inspection, ICT, and functional testing to ensure top-tier product reliability.

Turnkey Logistics: Efficient packaging and global shipping, ensuring rapid delivery and minimal lead times.

FR4PCB.TECHs engineering team collaborates closely with clients to optimize BOMs (Bills of Materials), perform DFM (Design for Manufacturability) analysis, and provide actionable recommendations for improving efficiency, reducing costs, and ensuring seamless assembly integration. This hands-on collaboration differentiates FR4PCB.TECH from traditional contract manufacturers, providing clients with both technical insight and production expertise.

Applications and Client Success Stories

FR4PCB.TECHs 110pcs prototype PCB assembly solution supports a wide range of applications:

IoT Devices: Compact, energy-efficient prototypes for connected sensors, smart home systems, and wearable electronics.

Industrial Automation: Low-volume control boards and sensor modules for pilot projects and prototype testing.

Medical Electronics: Small-batch PCBAs for monitoring and diagnostic devices, ensuring compliance and reliability.

Consumer Electronics: Innovative devices requiring rapid functional validation before large-scale production.

Recent client successes highlight FR4PCB.TECHs ability to deliver rapid, high-quality prototypes:

A European IoT startup collaborated with FR4PCB.TECH to produce 10 prototype boards for a wearable environmental sensor. The project achieved a three-week turnaround, allowing the client to conduct user testing and refine the product before securing investor funding.

A North American industrial automation company used FR4PCB.TECHs prototype assembly service to produce a batch of PLC control boards for a new line of robotic equipment. The rapid prototyping enabled the client to validate performance and thermal management, reducing the overall development timeline by 25%.

These examples demonstrate how FR4PCB.TECHs prototype service accelerates innovation, reduces risk, and provides clients with the flexibility to iterate on designs quickly.

Commitment to Quality and Standards

FR4PCB.TECH operates under strict quality control processes, certified with ISO 9001:2015, ensuring that all aspects of production from materials to assembly and testing meet international standards. The company also adheres to RoHS and IPC-A-610 compliance guidelines, guaranteeing environmentally responsible manufacturing and consistent product quality.

By combining state-of-the-art production technologies with robust engineering support, FR4PCB.TECH delivers a unique combination of speed, accuracy, and reliability, making it a preferred partner for global OEM and ODM clients seeking low-volume, high-quality PCB prototypes.

About FR4PCB.TECH

FR4PCB.TECH is a leading provider of advanced PCB and PCBA manufacturing services, specializing in OEM and ODM solutions. With end-to-end capabilities including design, fabrication, assembly, testing, and logistics, the company delivers high-quality, reliable, and cost-effective electronic manufacturing services across industries such as IoT, consumer electronics, industrial automation, and medical devices.

For more information on FR4PCB.TECHs China 110pcs prototype PCB assembly solution and turnkey PCBA services, please visit https://www.fr4pcb.tech/.

Source :Shenzhen Xindachang Technology Co.. Ltd

This article was originally published by IssueWire. Read the original article here.